Installation guide raft and baffle

Loke™ and Eira™ raft

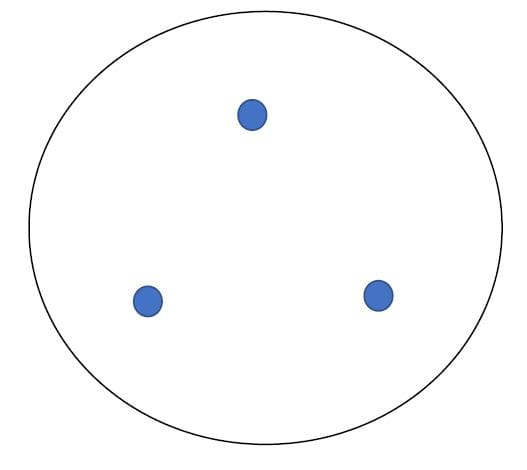

3 wires per circle (600 dm).

Larger circles, ovals and rafts are recommended 4-6 wire.

3 wires per circle (600 dm). Position as shown (as a triangle). Can be attached to the ceiling in one hook (collects all three wires in one hook, or attaches to three different hooks.

Installation guide acoustic raft

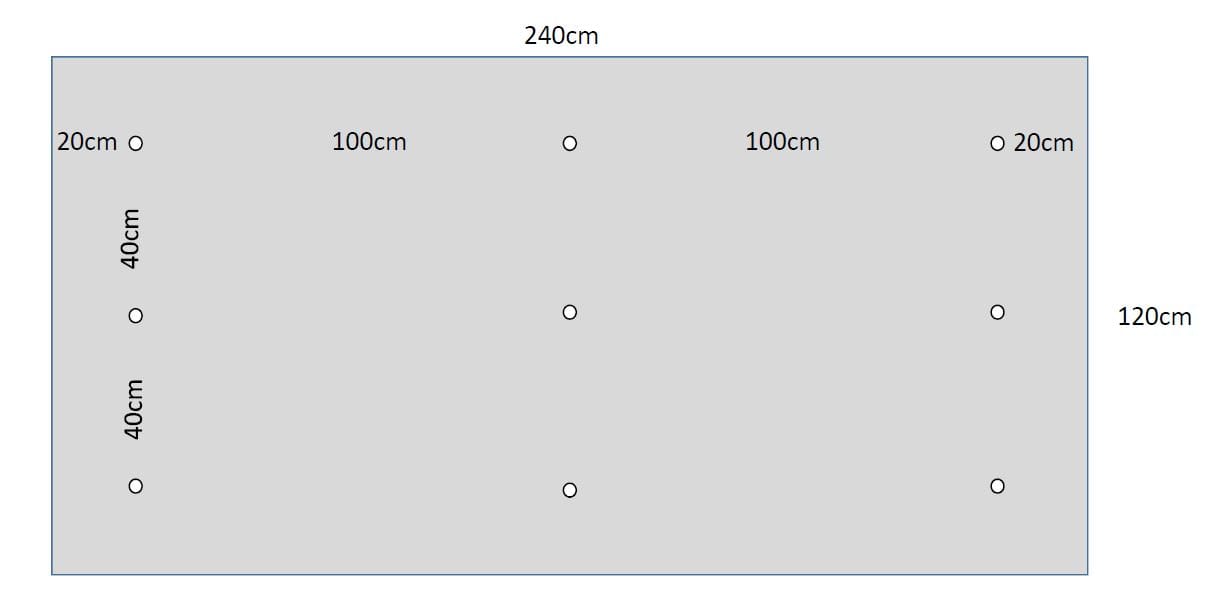

Measure and mark the 9 attachment points for the suspension screws. Fasten the screws and test that they are secure. It takes 3 people or a plasterboard lift to lift up the board and attach the wires.

NB! The boards should be mounted out of people's reach.

9 sets of wire fasteners are needed

NB: The fixing screw is screwed in as far as possible without perforating the visible side of the flange.

Suspension of Loke™ and Eira™ baffles, rafts and circles

General regarding suspension of acoustic absorbers.

Glass wool and mineral wool absorbers have a porous structure that makes them good sound absorbers.

The porosity means that special fasteners must be used for safe hanging. Special screws have been developed to ensure a firm hold in the wool/absorbent so that they can be hung in, for example, a floor partition using, for example, wires.

baffler

Vertically suspended absorbers

where the fixing screw is installed in the edge.

Ticks

Horizontally suspended absorbers

where the fixing screw is mounted on the surface.

No. 86026 / long screw: for vertically suspended baffles. Load capacity approx. 30 kg per piece.

No. 86028 / short screw: for both vertically and horizontally suspended floats/circles/ovals.

Load capacity approx. 12 kg per piece.

The carrying capacity is based on a density of the wool in the absorbent of 110

120 kg/m 3

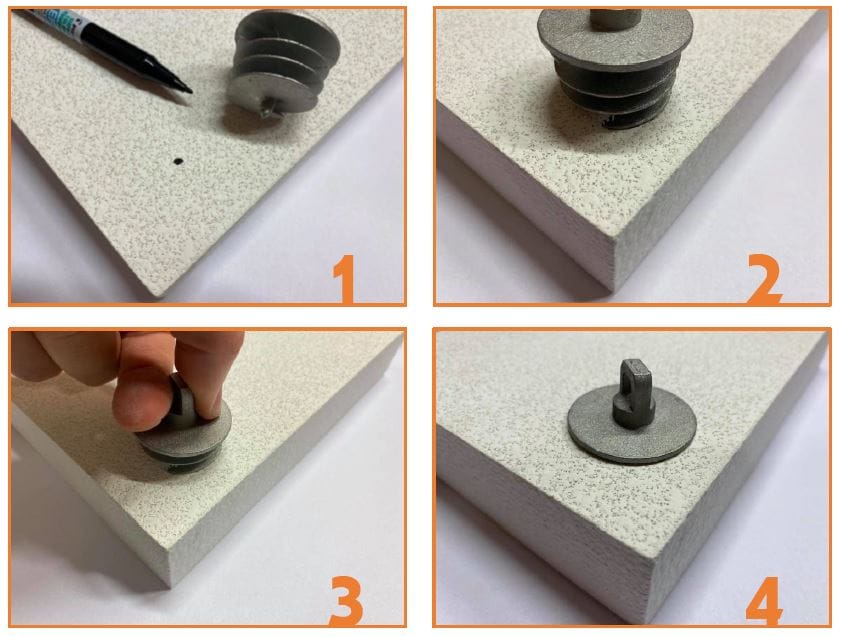

Installation

In general, the load-bearing capacity of the screw fasteners is so high that not many fasteners are needed to support the weight of the absorber.

The fixing screws are best screwed in by hand. It is important not to overtighten the screws. The use of mechanical tools is not recommended.

baffler

Fixing screws are placed in the edge of the baffle.

For a 60x120cm horizontal baffle, 2 fixing screws are used.

For longer baffles, it is recommended to follow the 60 CC principle. I.e. one fixing per 60 cm.

Ticks

Fixing screws are placed on the surface that will face the soffit/fixing base.

For a 120x240cm horizontal raft, 6 fixing screws are normally used.

Enough fasteners are used to adjust the angle of the raft as desired.

Installation option 1 - raft

No. 86028

The fixing screws are best screwed in by hand. It is important not to overtighten the screws. The use of mechanical tools is not recommended.

Load capacity approx. 12 kg per piece.

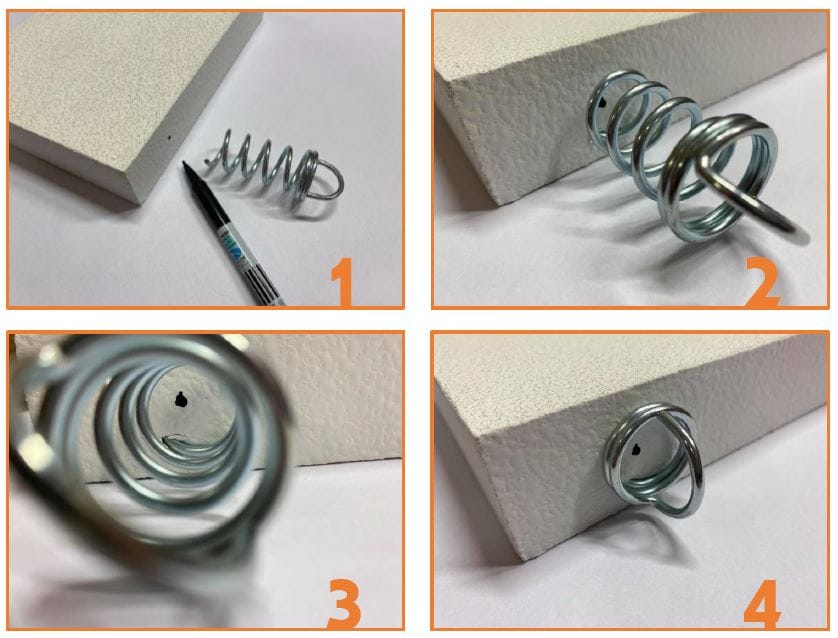

Mounting option 2 - baffle

No. 86026

The fixing screws are best screwed in by hand. It is important not to overtighten the screws. The use of mechanical tools is not recommended.

Load capacity approx. 30 kg per piece.

Floats and baffles (absorbers and diffusers) are hung in many ways and at many angles, depending on the desired purpose.

The wire suspensions are used to get the absorbers in the right position in relation to what you want to achieve.

The wire suspensions provide great flexibility because they can be attached where it is most appropriate in the absorber's edges and surfaces and in the building's structure (walls, ceilings, beams, etc.) to optimise the positioning of the absorber itself.

Wire suspensions therefore often hang at different angles from the absorber to the attachment point in the surrounding structure.

Some may perceive it as being crooked, but it is completely normal and very often necessary to get the absorber in the right position.

The wire suspension is therefore not part of the absorber but is a fastening device for placing the absorber in the correct position where other fastening devices are not appropriate.

When it comes to hanging vertically suspended baffles, both of the suspension screws we supply can

(part no. 86026 and 86028) are used as both have sufficient load-bearing capacity in relation to the absorbers' own weight.